With genetic improvement, the time it takes for broilers to reach a given target weight has been reduced. At the same time, in order to meet market demands, broiler processing weight requirements have become more precise.

While these two factors appear to be the easier route of improvement to the final product, reducing the established time to reach target weight presents a challenge for breeders. For example, it is normal for a flock to have a weight difference of 115g (0.25lbs) and 230g (0.25-0.50lbs) when the target weight is 1815g (4.00lb) and 3405g (7.50lb). This difference occurs even when chickens from the same strain are fed the same feed source, which clearly affects economic yield. So why do these differences in target weight occur?

Ventilation plays a big role in broiler performance and the resulting income.

Changes in the indoor environment significantly affect the growth performance of broilers, which are greatly affected by ventilation. Keepers must be responsible for managing house ventilation.

Growth and Income

A common way to compare growth rates of flocks of different ages is to calculate average daily gain (ADG), which is average body gain divided by processing age. Comparing these numbers can reflect differences between breeders. For example, on a small farm, some chickens ADG can reach 45g (0.10lb) while some can reach 50g (0.11lb)/day. The difference in these numbers means that chickens sent to the processing plant from the first breeder can reach 1770g (3.90lbs) at 39 days of age, while chickens from the second breeder can average 1950g (4.29lbs) at the time of processing . If the first breeder is raising chickens of the same weight as the second producer, it will need to be raised for 4 more days.

The difference in growth rate is more pronounced for heavy chickens. For example, in one flock, a broiler with a target weight of 3180g (7.00lbs) has an ADG of 50g (0.11lb), while another flock has an ADG of 59g (0.13lb). If both flocks were processed at 60 days of age, the first flock would have an average weight of 2995g (6.60lb) per bird, while the other flock would have an average weight of 3540g (7.80lb). At this growth rate, the first flock must be raised for 70 days of weight to reach the 60-day weight of the other flock - a 10-day difference in processing age.

In practice, flocks are usually processed at the same age. In this case, it is not practical to give "extra growing time" to slower growing flocks to catch up with faster growing flocks. Broiler farmers with low body weight gain will have significantly lower incomes. In addition, the profit of the contract company will also be significantly reduced. These examples illustrate that a small difference in production speed can have a large impact on the overall productivity of a broiler.

Effect of ventilation on chicken growth and feed conversion ratio

Changes in modern broilers have increased the importance of indoor environmental factors. To meet market demands, geneticists not only increased the growth rate of the flock, but also increased the carcass yield of the flock. The increased meat production of these birds was concentrated in the breast muscles, which made the broilers more sensitive to high temperatures; therefore, the difference in the performance of these birds was largely attributable to how farmers managed the ambient temperature of the house.

Geneticists have screened broiler chicken genes in order to increase broiler growth rates, primarily determined by broiler feed intake. If the temperature is too high, the broiler will not eat enough, and may not even have any appetite at all. A great function of house environmental management is to optimize ventilation programs, which can be done by evaluating the ventilation management of the grower and subsequent broiler performance.

If ventilation is not ideal at any time of the day, potential growth during that part of the day is lost and never regained.

For example, a 38-day-old broiler has 912 hours of growth. If the growth rate deviates from the target body weight 1815g (4.0lb) 115g, or 6.3%. This means that it takes 6.3% more time, or 57 hours, for broilers to reach their target body weight. More likely, the reduction is from several hours over a period of time, and growth rates would not be ideal under such conditions.

In addition to reduced growth rate, temperature problems may also affect growth performance by increasing feed consumption. If ventilation problems cause temperatures to be lower than ideal, the broiler will still eat enough feed and will grow, however, more energy will be expended to maintain normothermia than to grow. In this case, although the body weight gain will reach the target body weight, the production cost will increase because of the increased feed consumption. Temperatures below ideal, even for a few hours, can increase feed requirements and result in reduced growth performance.

Impact on cost and revenue

In terms of reducing the growth rate and increasing feed consumption to affect the growth performance of broilers, ventilation problems will greatly affect the production cost. Therefore, the result of unreasonable ventilation is the loss of profits for farmers and companies.

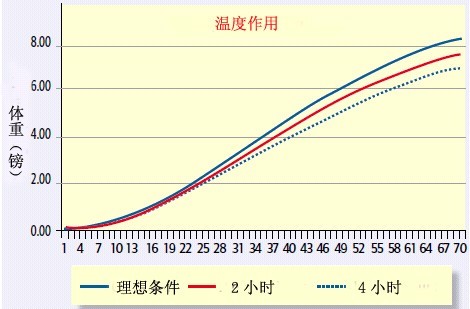

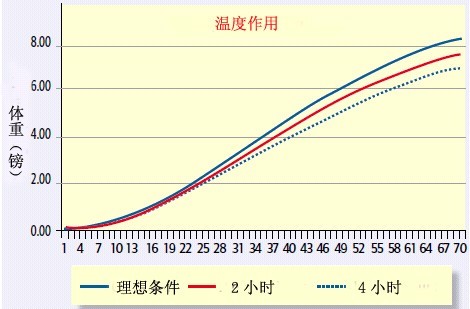

Figure 1. Effect of increasing ambient temperature on growth performance.

Figure 2. Companies' lost revenue when growth performance is less than ideal.

Figure 3. Age-related economic losses when chicken performance is suboptimal in a house.

Unreasonable ventilation at any time can adversely affect broiler performance (Figure 1). The blue line is the expected finish weight of the flock under ideal conditions. The red line shows the body weight the flock is expected to reach with 2 hours of overheating per day. The dashed line shows the body weight the flock is expected to reach with 4 hours of overheating per day.

The data from this graph shows that 38-day-old chickens have a weight difference of 160 g (0.35 lb) under optimal environmental conditions and 2 hours of high temperature per day, and 320 g (0.70 lb) of weight difference at 4 hours of high temperature. This means that for a house with 30,000 chickens, with 2 hours of poor ventilation in a 24-hour period, the flock can potentially lose 4762kg of birds.

Figure 2 illustrates the company's lost revenue when body weight is below optimal growth performance. If 1 million birds are assumed to be processed per week, at 38 days of age, carcass yield is 75%, meat prices are $1.56/kg ($0.71/lb), and 2-hour and 4-hour losses are $9.7 million and $19.4 million, respectively. For older flocks, losses will be greater. Based on this information, assuming that 10% of the chickens in the company are under poor growth conditions, the losses are still significant.

Figure 3 shows the age-related economic losses of underperforming chickens in a house. Based on this information, it is calculated that a stock of 20,000 chickens, 5 pens per year, is paid to the farmer at a price of $0.11/kg ($0.05/lb), and the target weight is reached at 38 days of age, with a loss of $1,750 and $1,750 at 2 and 4 hours, respectively. $3,500. Economic losses increase further for older flocks.

Conclusion

Modern chicken houses are able to control ventilation inlets through static pressure management. Both duct ventilation and evaporative cooling ventilation are very effective. However, producers must properly manage and maintain ventilation equipment. Otherwise, body weight and feed conversion ratios can be compromised, resulting in significant economic losses for breeders and integrators.

Clearly, proper ventilation and house environmental management procedures are important in reducing flock weight variability and maximizing profits for growers and integrators.